Nhazi nke ED copper foil:

1. Dịka arụmọrụ si dị, enwere ike kewaa akwụkwọ ED copper foil n'ụdị anọ: STD, HD, HTE na ANN

2. Dịka isi ihe dị n'elu si dị,ED ọla kọpa foilEnwere ike kewaa ya n'ụdị anọ: enweghị ọgwụgwọ elu na enweghị mgbochi nchara, ọgwụgwọ elu nke mgbochi nchara, nhazi otu akụkụ nke mgbochi nchara na ijikwa mgbochi nchara ugboro abụọ.

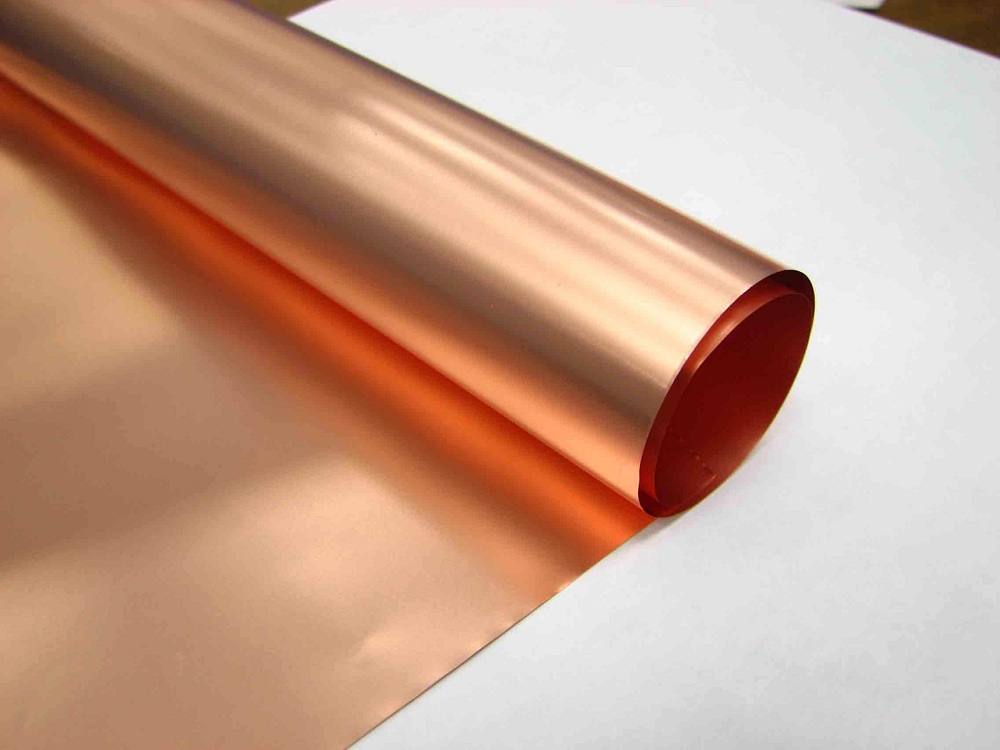

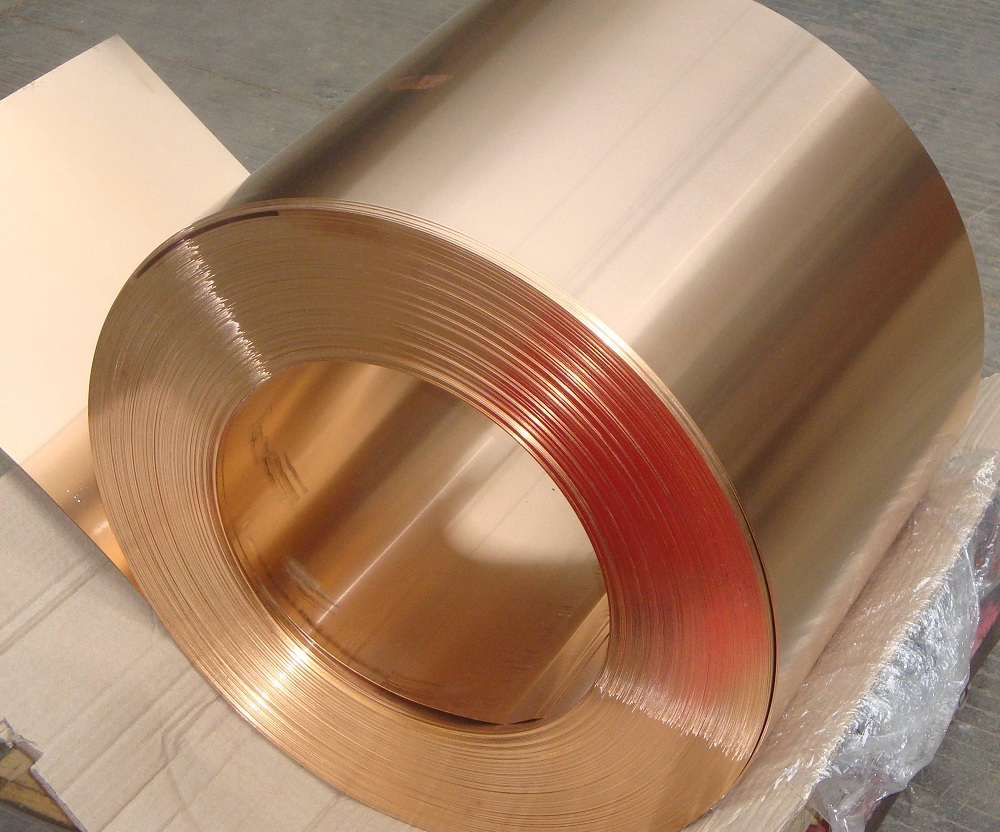

Site na ntụnye ọkpụrụkpụ ya, ọkpụrụkpụ aha nke na-erughị 12μm bụ obere mpempe akwụkwọ ọla kọpa electrolytic. Iji zere njehie na nha ọkpụrụkpụ ya, a na-egosipụtakwa ibu kwa mpaghara otu dịka mpempe akwụkwọ ọla kọpa electrolytic 18 na 35μm zuru ụwa ọnụ, otu ibu ya kwekọrọ na 153 na 305g / m2. Ụkpụrụ mma nke mpempe akwụkwọ ọla kọpa ED gụnyere ọcha nke mpempe akwụkwọ ọla kọpa electrolytic, iguzogide, ike, ogologo oge, ikike ịgbado ọkụ, porosity, iru ala elu, wdg.

3.ED ọla kọpa foilenwere ike kewaa ya n'ime usoro mmepụta nke ịkwadebe ngwọta electrolytic, electrolysis na post-processing dịka teknụzụ mmepụta foil ọla kọpa electrolytic si dị.

Nkwadebe nke elektrọtị:

Buru ụzọ tinye ihe dị ọcha karịa 99.8% nke ihe ọla kọpa mgbe ị gbasasịrị tankị ahụ n'ime ọla kọpa ahụ gbazere agbaze; wee sie nri na sulfuric acid na-akpali akpali, anyị wee nweta ọla kọpa sulfate gbazere agbaze. Tinye ọla kọpa sulfate n'ime ebe nchekwa ahụ mgbe njupụta ahụ ruru ihe achọrọ. Ọ ga-abịa na sistemụ mgbasa ozi ngwọta site na pipeline na ebe nchekwa ọkpọkọ na cell Unicom. Mgbe mgbasa ozi ngwọta ahụ kwụsiri ike, ọ nwere ike inye sel electrolysis ike. Electrolyte chọrọ ịgbakwunye oke surfactant kwesịrị ekwesị iji hụ na uru ọla kọpa dị n'ime ya, nhazi kristal, ike, porosity, na ihe ngosi ndị ọzọ.

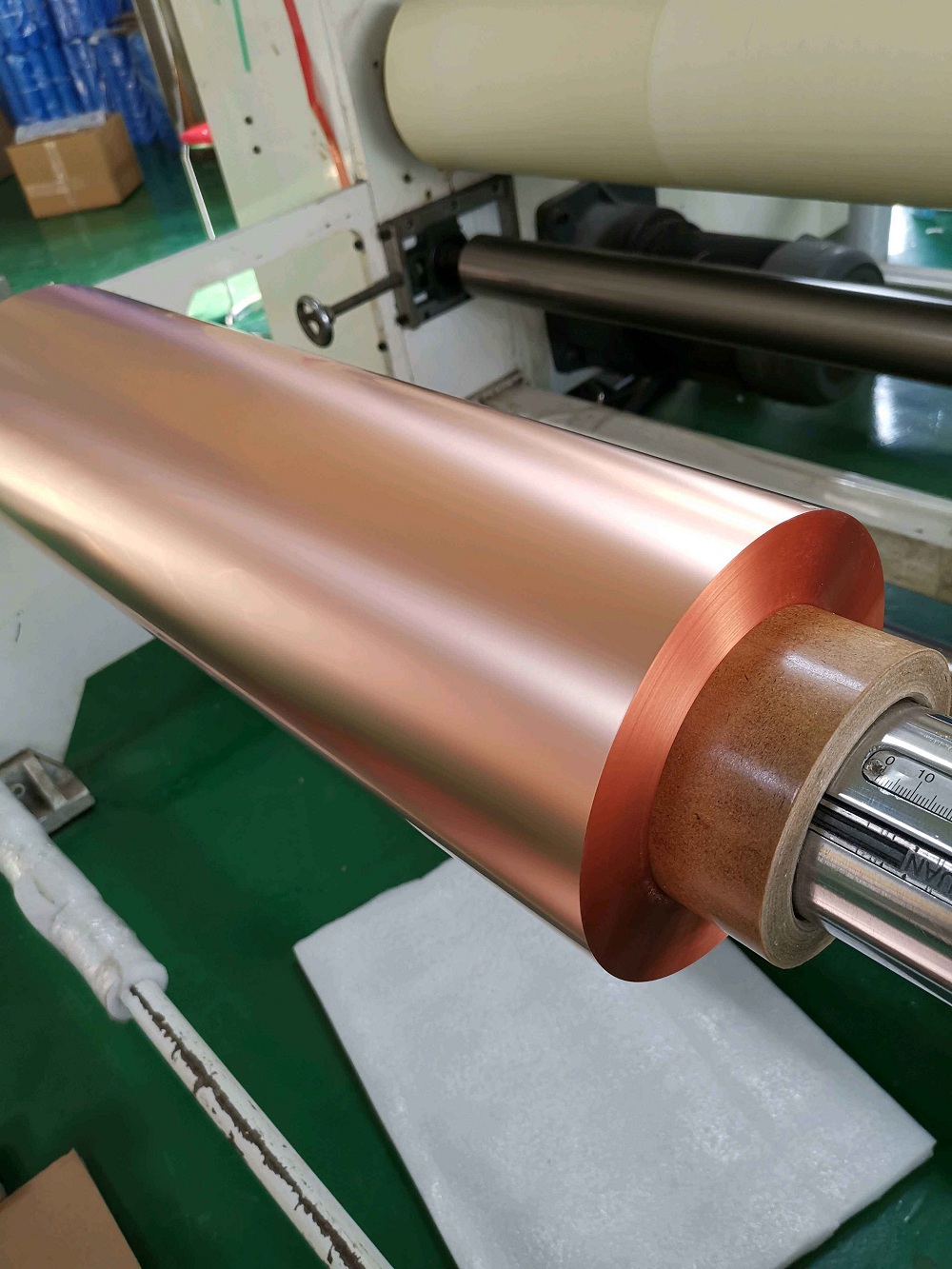

Usoro nke elektrọd na electrolysis

Katode Electrolysis bụ drum a na-agbanwe agbanwe, nke a na-akpọ katode roll. Ọ nwekwara ike iji eriri ígwè na-enweghị isi dị ka katode. Ọ na-amalite itinye ya na katode ọla kọpa mgbe ike gasịrị. Ya mere, obosara wiil na eriri ahụ na-ekpebi obosara nke foil ọla kọpa electrolytic; ọsọ ntụgharị ma ọ bụ na-agagharị na-ekpebikwa ọkpụrụkpụ nke foil ọla kọpa electrolytic. A na-ewepụ ọla kọpa e tinyere na katode ahụ mgbe niile, na-ehicha, na-akpọ nkụ, na-egbutu, na-akpọchi ma na-anwale ya mgbe e zigara ndị na-achọ ọrụ nke ọma. Anode electrolysis anaghị agbaze site na lead ma ọ bụ lead alloy.

Usoro nhazi anaghị ejikọta naanị na ọsọ nke electrolysis nke cathode ahụ, kamakwa yana ngwọta electrolyte ma ọ bụ njupụta, okpomọkụ, na njupụta ugbu a nke cathode n'oge electrolysis.

Usoro nhazi anaghị ejikọta naanị na ọsọ nke electrolysis nke cathode ahụ, kamakwa yana ngwọta electrolyte ma ọ bụ njupụta, okpomọkụ, na njupụta ugbu a nke cathode n'oge electrolysis.

Ihe eji atụgharị katode nke titanium:

N'ihi na titanium nwere nnukwu ike kemịkalụ na ike dị elu. Ọ na-apụ ngwa ngwa site na elu mpịakọta na obere porosity maka foil ọla kọpa electrolytic. Katode titanium na usoro electrolytic ga-emepụta ihe na-adịghị mma, ya mere ọ chọrọ nhicha mgbe niile, egweri, ịchacha, nickel, chrome. Enwere ike itinye ihe mgbochi corrosion, dị ka nitro ma ọ bụ nitrous aromatic ma ọ bụ aliphatic compounds na electrolyte, ọnụego passivation na-ebelata katode titanium. Ụfọdụ ụlọ ọrụ na-ejikwa katode ígwè anaghị agba nchara iji belata ọnụ ahịa.

Oge ozi: Jenụwarị-09-2022